Solvent Cleaning Equipment

-

🌟 What Is Vapour Degreasing?

Solvent-Based Precision Cleaning Explained

Vapour degreasing is a widely-used solvent cleaning process that uses hot solvent vapours to clean components effectively. While traditionally performed with chlorinated or fluorinated solvents like Perchloroethylene, vapour degreasing continues to be a go-to method for industrial cleaning due to its simplicity, reliability, and high performance.

✅ How Vapour Degreasing Works

The vapour degreasing process involves the following steps:

-

Heating the Solvent

The cleaning solvent is heated until it reaches its boiling point, creating a dense vapour. -

Condensation on Cooler Surfaces

When this hot vapour makes contact with a cooler component (e.g., metal), it condenses into a liquid, releasing latent heat. This action dissolves oils, greases, waxes, and other surface contaminants. -

Gradual Equilibration

As the component heats up and reaches the same temperature as the vapour, condensation stops, completing the cleaning action. -

Evaporation for Drying

Once removed from the vapour zone, any residual solvent evaporates due to the retained heat in the component, leaving it clean and dry—no additional rinsing or drying required.

✅ Modern Vapour Degreasing TechniquesModern solvent cleaning systems enhance traditional vapour degreasing with advanced features like:

-

Boiling Solvent Immersion

Ensures thorough cleaning by fully submerging the parts in solvent. -

Ultrasonic Agitation

Boosts cleaning power, especially for delicate components or difficult-to-reach areas. -

Final Vapour Rinse

Provides a residue-free finish, ensuring top-tier cleanliness.

This multi-stage approach ensures consistent, high-purity cleaning, ideal for critical sectors like aerospace, medical, electronics, and precision engineering.

✅ Types of Solvent Cleaning EquipmentThere are three primary categories of solvent cleaning machines, as outlined by European Standard EN12921:

🔒 Closed Solvent Cleaning Equipment (Types III–V)

-

Fully Sealed Chambers

Cleaning, rinsing, and drying happen inside a completely sealed environment. -

No Operator Exposure

Solvent vapours are contained, ensuring maximum safety. -

Carbon Abatement Systems

Often integrated to manage emissions. -

No External Venting

Ideal for non-flammable solvents.

🔐 Enclosed Solvent Cleaning Equipment (Types II–III)

-

Solvent Containment

The process is contained within an enclosure to isolate the solvent from the operator. -

Higher Safety Standards

Designed for mid-to-high-volume precision cleaning. -

Suitable for Non-Flammable Solvents

Offers robust environmental controls.

⚠️ Open Solvent Cleaning Equipment (Type I)

-

Traditional Open-Top Systems

Exposes solvent vapour to the operator. -

Lower Safety & Environmental Control

These systems are becoming less common due to regulatory concerns.

✅ Explore Our Solvent Cleaning Equipment

We offer a wide range of solvent cleaning machines to suit different process needs and compliance requirements:

-

🔹 Closed Automatic Systems

Fully sealed, high-performance cleaning for maximum safety and efficiency. -

🔹 Enclosed Automatic Systems (Cleanseal)

Enhanced containment and safety for mid-to-high-volume applications. -

🔹 Open Manual Systems (Miniclean, Compac)

Cost-effective and simple cleaning solutions for less demanding applications.

👉 Click here to view our full equipment range or Contact our team for expert advice and a tailored solution.

✅ Why Choose Vapour Degreasing?

-

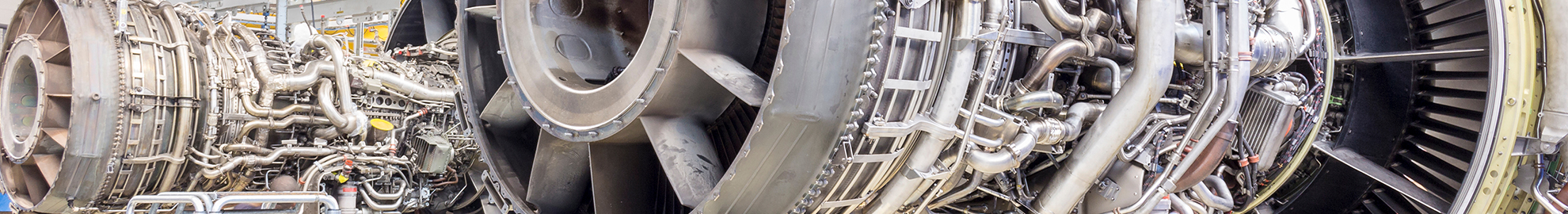

⚙️ Precision Cleaning

Ideal for metal parts, PCBs, medical instruments, and more. -

🌿 Environmentally Friendly

Compatible with safer solvents like Tergo™ MCF and Tergo™ HDF. -

✨ Residue-Free Finish

Leaves parts dry, clean, and free of contamination. -

💼 Proven Industry Method

With decades of industry use, vapour degreasing offers trusted and reliable cleaning.

-