Open, Manual Equipment

MiniClean

-

🔍 Key Features:

-

🧱 Compact Design – small footprint, fits easily into tight spaces

-

🔌 240V Single Phase Supply – plug-and-play setup

-

💨 Compatible with MicroCare Tergo solvents

-

🛞 Wheels & Handles – easily move between workstations

-

🧊 Refrigerated Cooling System

-

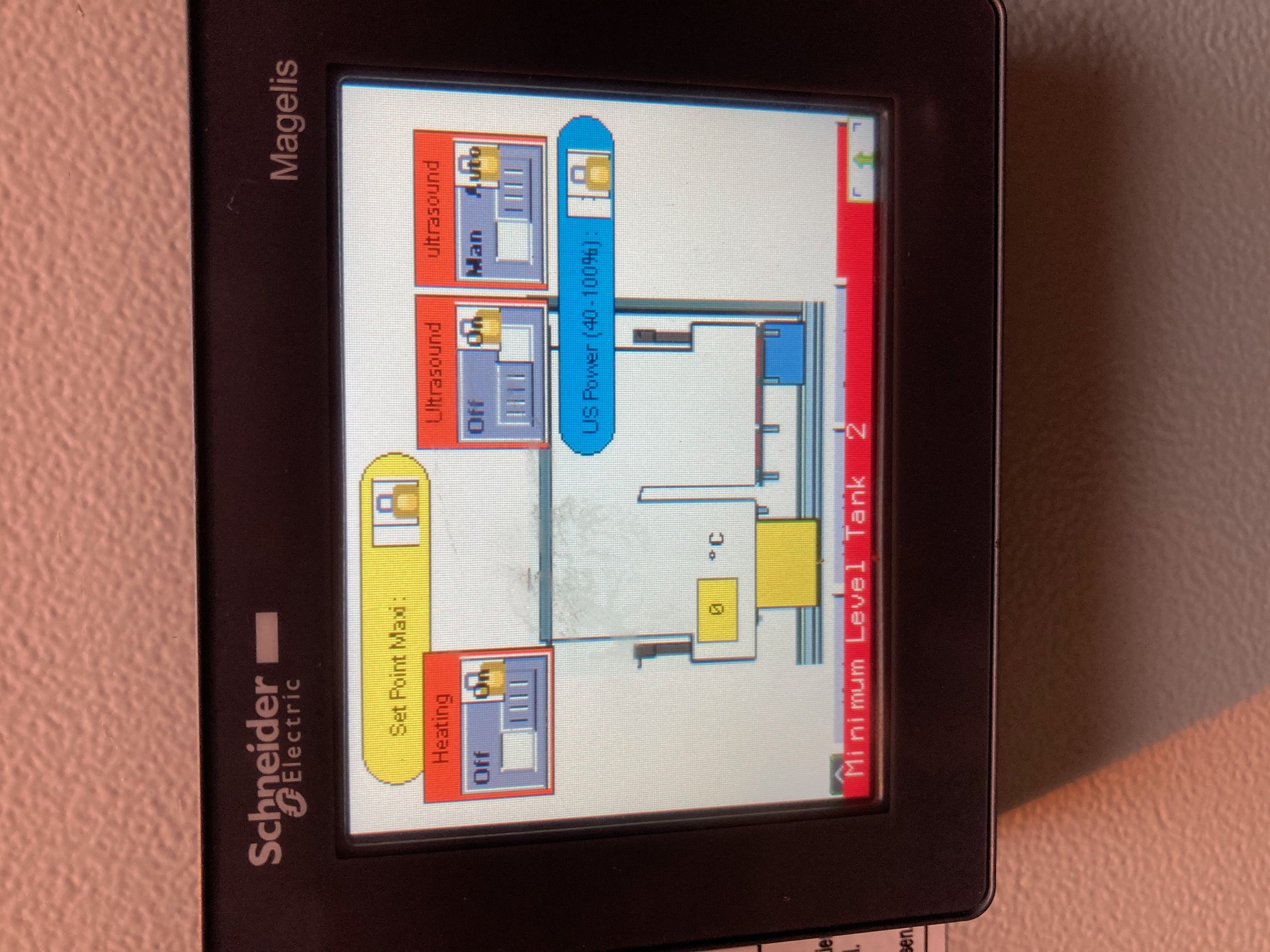

🔊 Ultrasonic Immersion Cleaning – for precision results

-

💡 PLC Control Panel – intuitive operation interface

-

💰 Low Energy & Running Costs – environmentally friendly

-

🌫️ Optional Rim Ventilation Kit – for methylene chloride use

-

🔧 Electric Heating – efficient temperature control

-

🧼 MiniClean – Solvent Cleaning System

Big Cleaning Power. Small Footprint. Maximum Efficiency.

The MiniClean by MEG S.r.l is a fully featured, compact solvent cleaning machine designed for low-volume production and R&D environments. Despite its small size, it delivers industrial-grade cleaning performance—ideal for precision industries that demand quality without compromise.

🧰 Designed for Mobility & Efficiency

-

📦 Compact footprint – Perfect for limited lab space

-

🔋 Energy-efficient operation – Reduces power and solvent consumption

-

🚶 Highly mobile – Easy to relocate and integrate into flexible workspaces

-

🧼 Full-featured cleaning – Includes high-end solvent technology typically found in larger systems

🎯 Ideal Applications

-

🧪 Development labs & prototypes – Clean small batches or sample runs

-

🔬 Electronics & PCBs – Remove flux, oils, and particulates with precision

-

✈️ Aerospace components – Ensure high-reliability performance

-

🏥 Medical devices – Low-bioburden cleaning for critical parts

🌱 Performance with a Lower Environmental Impact

-

♻️ Solvent-efficient – Maximizes cleaning with minimal waste

-

💨 Low emissions – Clean results without environmental compromise

-

🔧 Precision technology in a small format – Clean results that rival larger machines

MiniClean is proof that small-scale doesn’t mean small performance.

Perfect for innovators, precision manufacturers, and cleanroom environments.